IMPORTANT

The Prodways Hotline is exclusively reserved for users of Prodways ProMaker printers who need technical assistance.

Do you need technical assistance for your ProMaker printer?

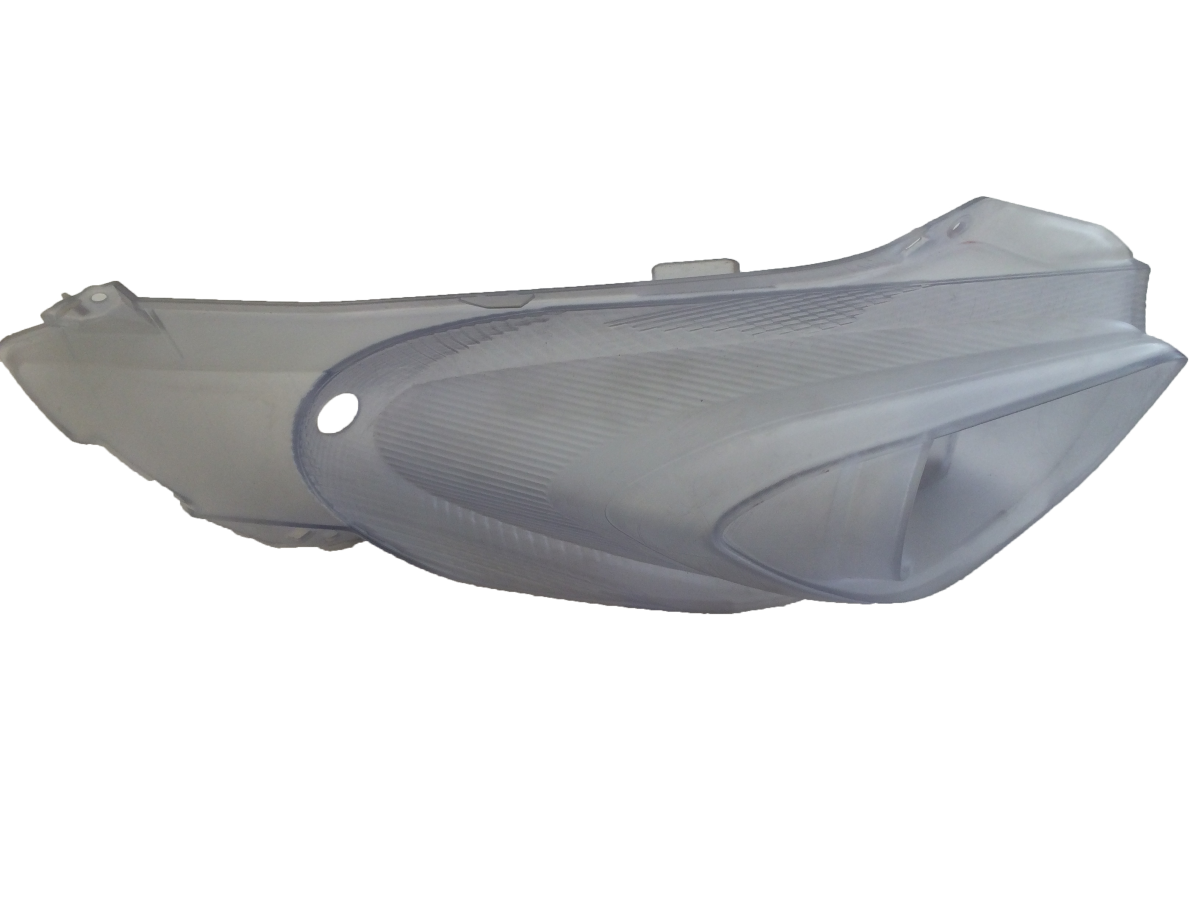

Perfectly adapted for industries such as the medical, electronic, aerospace and automotive markets that require precise and long-lasting models, PLASTCure ABS materials allow you to print high precision parts that are resistant to moisture and temperature.

Specific features of PLASTCure ABS 3650:

PLASTCure ABS 3650 is compatible with all our ProMaker L series products

*Preliminary data. Performance characteristics of these materials may change according to product application, operating conditions, material combined or end use.