IMPORTANT

The Prodways Hotline is exclusively reserved for users of Prodways ProMaker printers who need technical assistance.

Do you need technical assistance for your ProMaker printer?

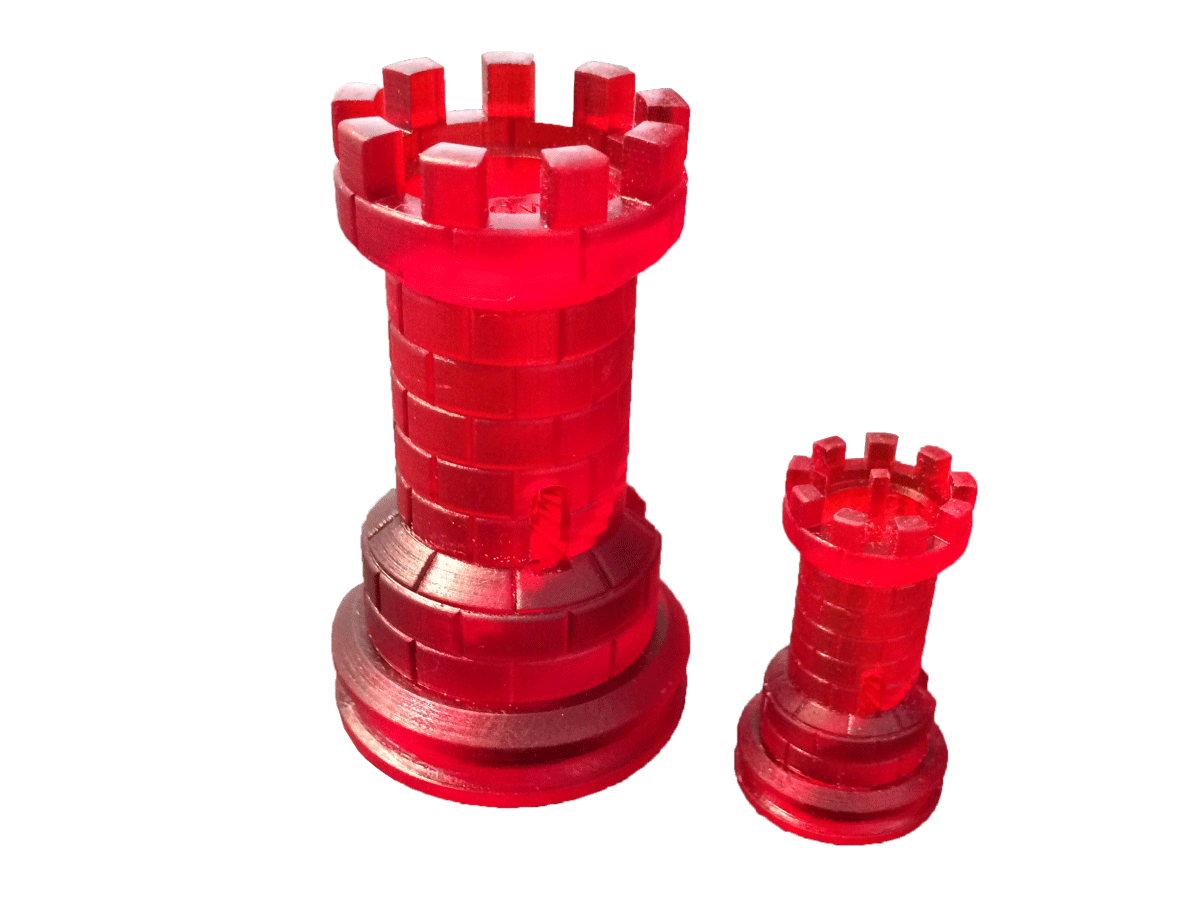

Perfectly adapted for the manufacturing of lost-wax casting parts, PLASTCure Cast materials meet the high expectations concerning the treatment chain and offer a very low residual ash content.

Specific features of PLASTCure Cast 100 :

PLASTCure Cast 100 is compatible with all our ProMaker L series printers

*Preliminary data. Performance characteristics of these materials may change according to product application, operating conditions, material combined or end use.