IMPORTANT

The Prodways Hotline is exclusively reserved for users of Prodways ProMaker printers who need technical assistance.

Do you need technical assistance for your ProMaker printer?

Additive manufacturing applications in the automotive industry are growing in number and adapting to the specific nature and constraints of this rapidly expanding s

ector.

Additive manufacturing has opened new avenues at each step of automotive production: across the phases of functional prototyping, design and tooling, through to series part production. The automotive industry is one of the pioneers in the use and integration of additive manufacturing in its processes.

Prodways’ technologies and services make it possible to design parts with complex geometries that are difficult or impossible manufacture with traditional methods, and to reduce the weight of components to minimize harmful emissions and optimize energy consumption. Additive manufacturing eliminates the need for tooling and thus considerably reduces costs and time for the development of your prototypes and the rapid-manufacturing of durable and tough functional parts. It also provides a new way to meet to the growing need for small series of personalized parts.

At present, Prodways has developed a wide range of solutions specifically dedicated to the automotive industry.

As part of the Prodways group, INITIAL is a resource center specializing in product development, additive manufacturing and production.

A wide range of ongoing services is also available for the automotive industry.

We offer a wide range of procedures and materials to meet your needs in terms of accuracy, surface, robustness, etc.

Internal prototyping methods enable high reactivity in the production of concept validation models.

Do you need to reduce stock and cost for small or limited series? We provide customized local manufacturing solutions, ensuring timely, responsive service.

We quickly integrate series manufacturing methods through our Tooling Service.

Do you want to keep a unique object in your possession?

Do you have a damaged tool requiring repair, but don’t have access to updated specs or replacement parts?

The potential offered by 3D scanning is considerable. Our team will help you select the offer best suited to your needs.

Quality control (ISO 9001:2008) is implemented to ensure satisfaction.

For more information about made-to-order parts, please contact us.

Prodways is opening up new opportunities for innovation and production by offering the most efficient additive manufacturing solutions and technologies for the automotive industry.

Based on 3D printing technologies that revolutionize existing technology, combined with a highly-skilled R&D team, Prodways provides you with a unique solution for industrial production, enabling you to be the most competitive in your market:

The MOVINGLight® DLP, a revolutionary technology patented by Prodways, is a photopolymerization process for producing prototypes or functional parts with very high resolution and at very high speeds, by polymerizing photosensitive resins with moving DLP (Digital Light Processing) UV rays.

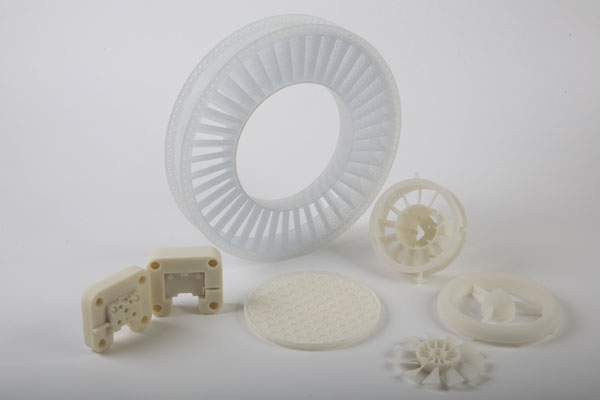

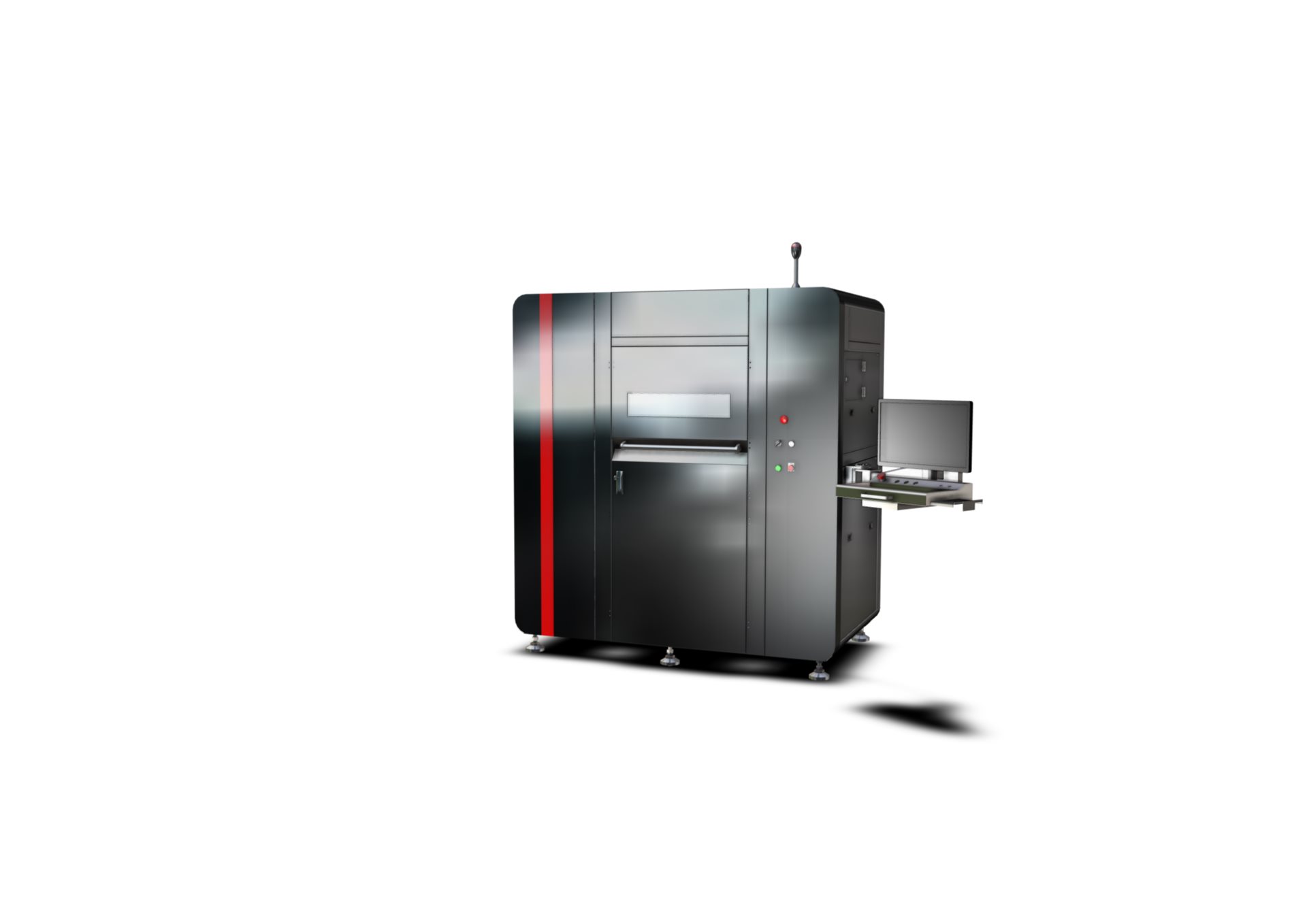

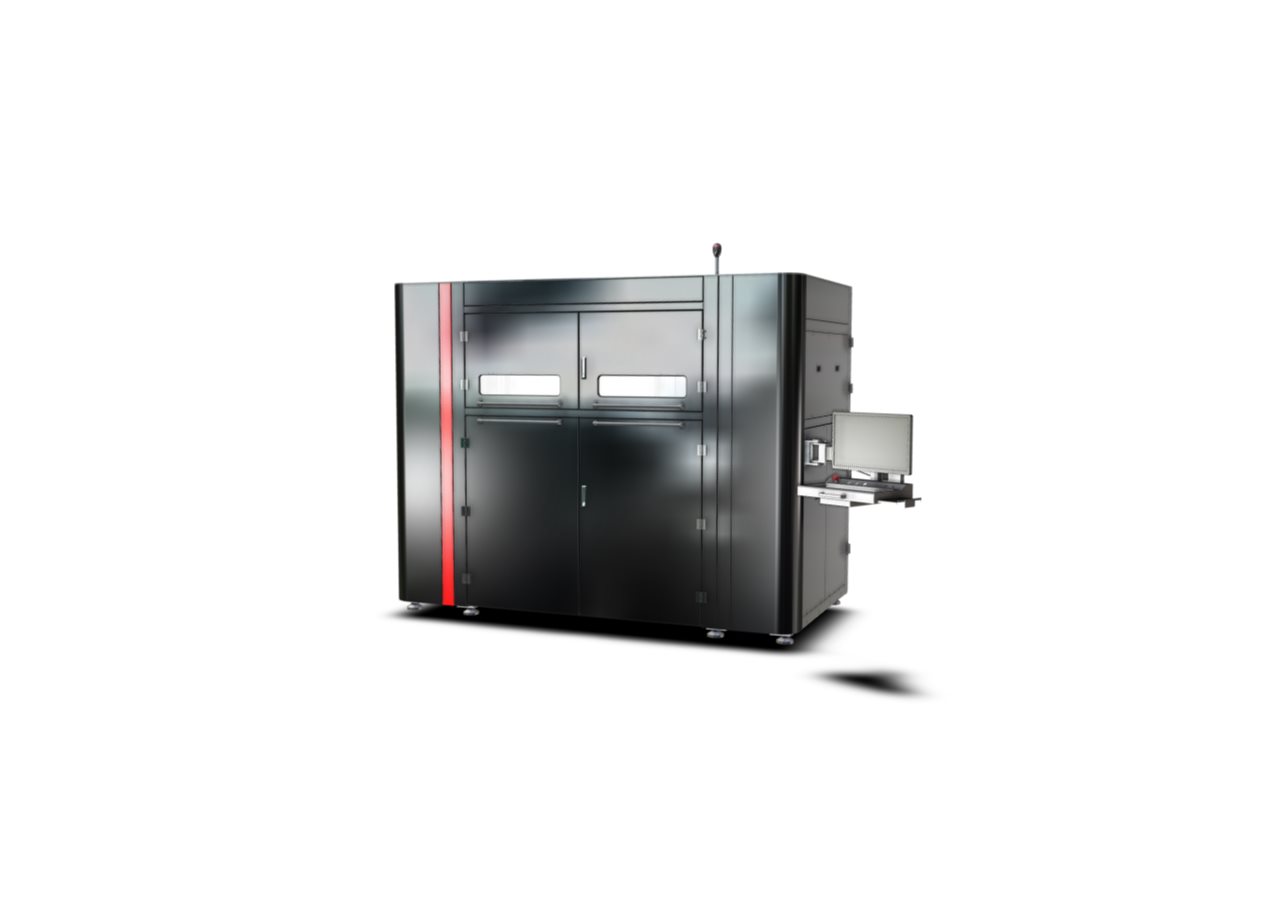

Our range of ProMaker P Series printers brings state-of-the-art industrial production capabilities for resistant thermoplastic functional prototypes and rapid manufacturing. Prodways technology delivers amazing productivity while reducing operating costs, with the highest levels of accuracy and precision for all your parts and the best thermal stability for optimized mechanical properties.

At the heart of Prodways’ expertise is the creation of premium, composite, sintering powder and hybrid additive manufacturing printing materials. Our materials boast high-performance mechanical properties (resistance and elasticity), physical and aesthetic properties and provide unrivalled stability over time.

Thanks to our industrial and R&D partners and internal material development team, Prodways offers a range of materials and is constantly developing high-performance premium materials for new and promising applications in the automotive industry.

Prodway’s MOVINGLight technology® uses DLPs operating with a wavelength of 365 nm and using very high power LEDs. This combination allows the use of resins with superior properties compared with competitor. Prodways has a full range of polymerizable resins to meet all your requirements – even the most demanding.

Thanks to its unique capacity to process heavily loaded and high-viscosity (pasty consistency) materials, Prodways has unlimited potential for the development of new viscous resins.

Prodways polymer powders for laser sintering have been developed to offer the best printer-material combination in order to meet the most demanding industrial needs, with a large range of resistant thermoplastics for your prototypes and functional parts.