IMPORTANT

The Prodways Hotline is exclusively reserved for users of Prodways ProMaker printers who need technical assistance.

Do you need technical assistance for your ProMaker printer?

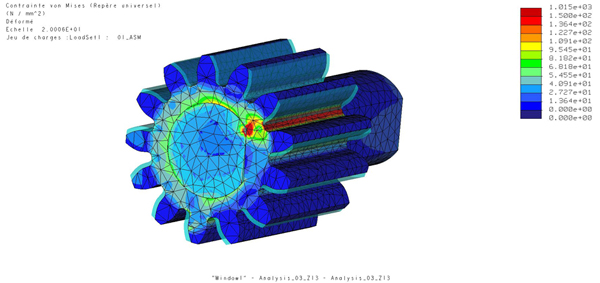

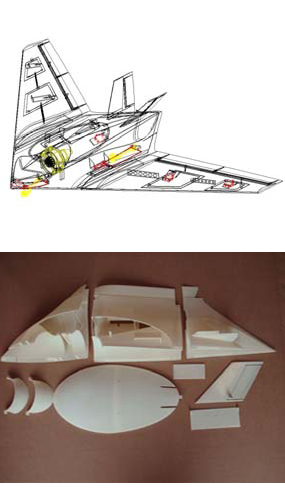

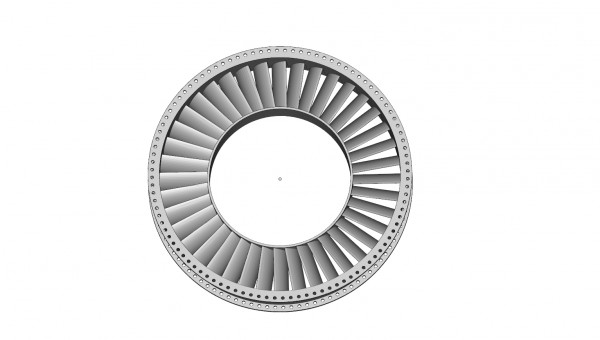

Prodways offers innovative technologies and services that make it possible to design and manufacture parts with complex geometries or with specific aerodynamic properties, which might be impossible to manufacture with traditional methods, for engines, turbines, wings or cabin interior components. The technologies and services made available by Prodways can effectively meet the needs of the aerospace industry, and are also well-suited for many applications in the civil defense and military robotics sectors.

You can now design and produce lighter parts, increase the performance of your critical components and reduce your inventory with on-demand parts manufacturing. Our additive manufacturing solutions eliminate the need for tooling and help reduce your costs while shortening your development and manufacturing cycles for prototypes and functional parts.

Based on existing resources and experience of the Group Gorgé, to our knowledge, we are the only one player in the 3D additive manufacturing industry to have promptly assembled a team and resources to manage projects for the defense industry. An ad-hoc organization will be created, combining aerospace division employees and Groupe Gorgé’s affiliates who are qualified to deal with the project as a whole.

Based in the European aeronautics hub of Toulouse, France, the Prodways Group’s new Aerospace division has a showroom dedicated to the aerospace sector, showcasing our knowledge and technology offerings. Presented in this showroom are specialized tooling applications that are already in use in industrial operations at aeronautical manufacturing sites and examples of embedded parts developed on test equipment, which are entering mass production. This unique offering of the Prodways Group, encompassing expertise in the development of machines, materials and applications, will enable the Group to offer extraordinary benefits to its collaborative customers, achieving the exacting quality and productivity standards required by this industry.

The Prodways Group Aerospace division is backed up by the industrial experience of:

AIRBUS HELICOPTER, DASSAULT AVIATION, AIRBUS DEFENCE AND SPACE, TURBOMECA, SAGEM, CNES, THALES, SNECMA MOTEUR, SMA (Groupe SAFRAN), VISION SYSTEM AERONAUTIC, COMPOSITE INDUSTRIE, REXIAA, CATHERINEAU, AIRCELLE, TECHSPACE, RUAG ET CASSIDIAN, SOGECLAIR AEROSPACE, WANDERCRAFT, INFOTRON™. THEY ALL TRUST INITIAL-PRODWAYS, ECA GROUP AEROSPACE AND PRODWAYS GROUP.

Prodways is the unique in the 3D printing sector, having a dedicated aerospace showroom for aeronautics, space and on-board equipment, located in the Aerospace Valley in Toulouse, France – the most significant innovation “pôle de compétitivité” in the world in the field of aeronautics, space and embedded systems, spanning two regions with 124,000 industrial employees and 8,500 researchers and scientists. It is a worldwide performance test center for aerospace materials and a center for structural testing.

This location is a true showcase of the knowledge and offerings of the Prodways Group:

PRODWAYS DIVISION AEROSPACE – ECA GROUP

Show Room – ZAC de Saint Martin du Touch

6 Impasse Alice Guy

31025 Toulouse Cedex 3 FRANCE

Contact Laurent ASTIER at aerospace@prodways.com

Phone: +33 (0)4 50 69 33 73

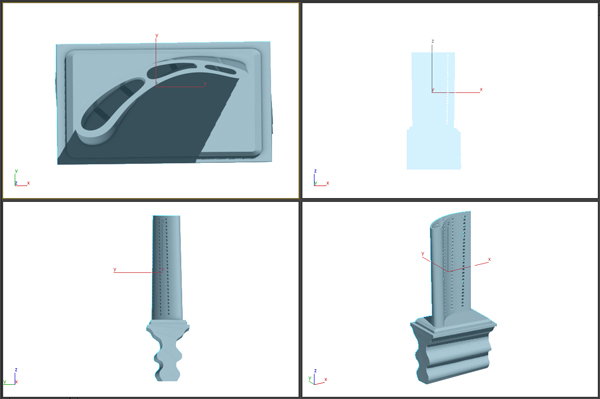

Our Design Development and Part Production Center use highly technical polymers and metallic materials. From the creation of prototype parts through to the manufacturing of flight parts, we propose solutions tailored to your specifications.

Our Development and Production Center, certified ISO 9001, is capable to providing valuable services:

Confidentiality: We guarantee full project confidentiality

Flexibility: The large production facility ensures continual production of your parts

Global Offer: A dedicated project manager will ensure full coordination for each phase of product development. He/she works closely with Product Design & Engineering experts through production and finalization.

Our creative and design team provides quality service (ISO 9001) and advice on the choice of materials to be used and the technologies best suited to your projects. Whether you are a manufacturer of engines or complete vehicles, we offer solutions that can be customized to meet your needs.

Additive manufacturing is a rapid process allowing innovative development of all your projects. We offer a wide range of materials to meet your needs. The shape, adaptability and functionality of your parts can therefore be validated.

We have been providing specialized testing for production units as well as test equipment for more than 30 years. Applications may include:

We provide one of the largest production facilities in France and can provide materials well-suited to the environment and the use of your parts:

Plastic Additive Manufacturing

Our expertise in additive manufacturing and the capacity of our production facility allow us to revolutionize the “traditional” design of parts by using efficient structural methods and topological optimization.

Using your specifications, we can:

3D control by comparison is a modern and effective means to analyze and validate multiple parts.

Prodways is offering the most efficient additive manufacturing 3D printers and materials for the aerospace and defense industries. With our revolutionary 3D printing technologies and a highly skilled R&D team, Prodways provides industrial production solutions to meet a wide range of 3D printing needs and applications.

We accelerate our customers’ innovation and open up new opportunities for high performance materials for R&D departments with our open material strategy on all our printer ranges.

Our premium SLS printers are the perfect solution for building strong and durable plastic parts with high mechanical performance for:

Prodways technology delivers amazing productivity while reducing operating costs, with the highest levels of accuracy and precision for all your parts and the best thermal stability for optimized mechanical properties.

Our wide range of PA12 and PA11 grades materials, including a fire-retardant PA11 powder certified for aeronautics, allow for the largest range of applications while our high-temperature-capable configuration enables you to process high performance materials like PA6.

For more information about:

Based on a revolutionary photopolymerization process, our ProMaker 3D printers offer an unparalleled combination of high resolution and speed for:

Prodways provides a complete range of innovative and hybrid resins to meet all your aerospace industry requirements, including ABS resins for resistant functional parts, rigid resins for high thermal stability, castable resins for lost-wax casting parts and ceramic pastes.

For more information about:

Thanks to our industrial and R&D partners, Prodways offers and is constantly developing high-performance premium materials for new and promising applications in the aeronautics, aerospace and defense sectors.

Our polymer powders for laser sintering have been developed to offer the optimum printer-materials combination for your application and meet even your most demanding industrial needs. Our polymer powders meet the requirements for manufacturing end-use complex parts or prototypes for a wide range of applications for aerospace and defense industries:

Want to know more about our complete powder offer Plastic powders for laser sintering.

Case studies: polyamide powder PA12 – UAV manufactured in several pieces – Client Malcom Nicholls Limited.

Our UV polymerization technology (365nm wavelength) is designed to work with premium liquid resins, and also with composites in the form of pastes that contain high levels of ceramic, metal, fibers, or nano-particles. We open up new channels for developing applications with mechanical properties that are currently not found in additive manufacturing.

Case studies: PlastCure ABS3650 – Lost wax casting of turbine blades.

Prodways provides a complete range of UV polymerizable liquid resins to meet all your requirements (even the most demanding) in the aerospace industry:

Want to know more about our Liquids resins for photopolymerization.

Due to our unique capability to use high viscosity materials (paste consistency) that are heavily loaded, Prodways has unlimited potential for the development of new viscous resins

Want to know more about our Ceramic resins for photopolymerization

The aeronautics and aerospace industries are at the front line of a strictly-regulated marketplace. Mastering the standards and fully maintaining aeronautics and aerospace certification is a key strategic resource that the Prodways Group shares with its partners. Whether engineered for passenger transit or military applications, the extremely tough safety and reliability requirements target every single link in a procurement chain interlinking a hugely diverse cross section of suppliers and subcontractors.

The Prodways Group subsidiaries are certified and regularly audited:

• Based in the European aeronautics hub of Toulouse, France, the Prodways Group’s new Aerospace division has a showroom dedicated to the aerospace sector, showcasing our knowledge and technology offerings.

• Presented in this showroom are specialized tooling applications that are already in use in industrial operations at aeronautical manufacturing sites and examples of embedded parts developed on test equipment, which are entering mass production.